Herbs and leafy greens are some of the most common (and surprisingly resource-intensive) crops in our food system. A handful of basil or a head of romaine may seem simple, but the way they’re grown, shipped, and priced reflects a global agricultural model that is increasingly unsustainable, both economically and environmentally.

Over the last five years, food prices have surged at double the rate of general inflation, driven by fuel costs, supply chain disruptions, climate events, and labor shortages. In Canada, the average cost of vegetables has risen by more than 25% since 2020, and price hikes show no signs of slowing down.

The United States paints a similar picture. Food prices have risen by 23.6% since 2020, and even in the EU and Australia, food inflation has recently peaked as high as 15% and 20%.

Meanwhile, droughts, floods, and heatwaves have disrupted harvests from California to Spain, exposing the fragility of long-distance food supply chains. As costs rise and access declines, more people are asking: Is there a better way to grow what we eat?

The answer is yes.

Industrial Agriculture: Productive but Unsustainable

Today’s dominant model of food production is built around industrial-scale, soil-based farming — a system optimized for volume, not resilience or locality. It delivers enormous quantities of produce, but at a steep cost:

- Land and Resource Use: Nearly half of the world’s habitable land is used for agriculture and just one head of lettuce can require up to 250 liters of water to grow.

- Mass Inputs: To maintain productivity at scale, global agriculture uses an estimated 3.5 million tonnes of pesticides annually — affecting soil, waterways, and human health.

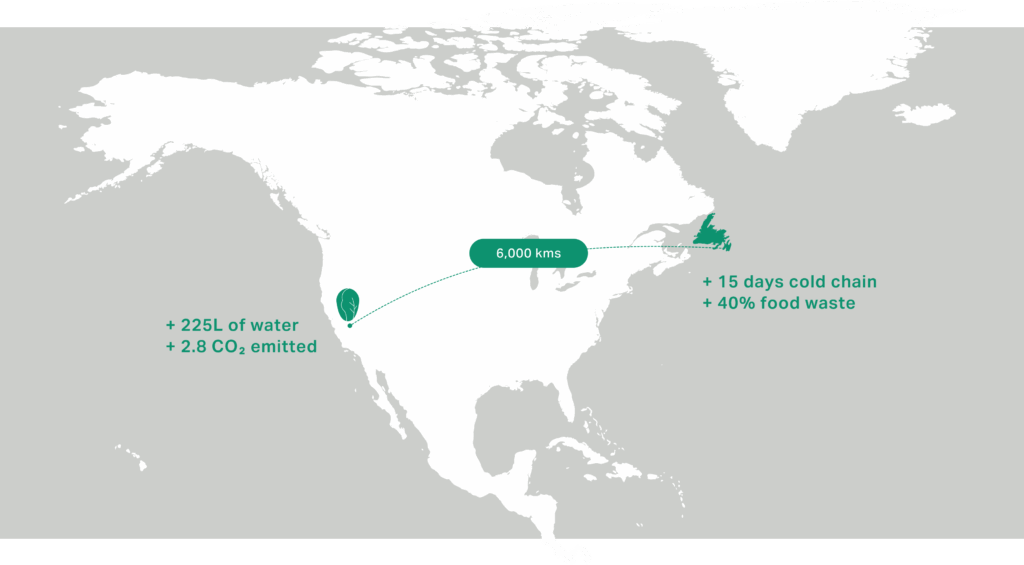

- Energy, Emissions & Transport: Agriculture accounts for 11-31% of global greenhouse gas emissions — leafy greens alone often travel over 2,000 kilometers in cold storage before reaching consumers (ask us how we know).

- Packaging & Waste: As much as 40% of produce is lost or discarded before it’s eaten, often due to spoilage, shelf-life limits, or nutrient degradation in transit.

Despite its inefficiencies, industrial agriculture continues to dominate because it’s heavily subsidized. In the U.S., more than $30 billion per year goes toward farm subsidies — reducing the cost of production for large-scale operations and keeping grocery prices artificially low. But these subsidies don’t change the underlying math: high water use, long-distance shipping, and massive food waste are still part of the price — even if consumers don’t see it on the receipt.

While this system helped feed the 20th century, it’s ill-equipped for the 21st, where climate resilience, sustainability, and local access matter more than ever.

The Rise of Modern Alternatives — and Their Limitations

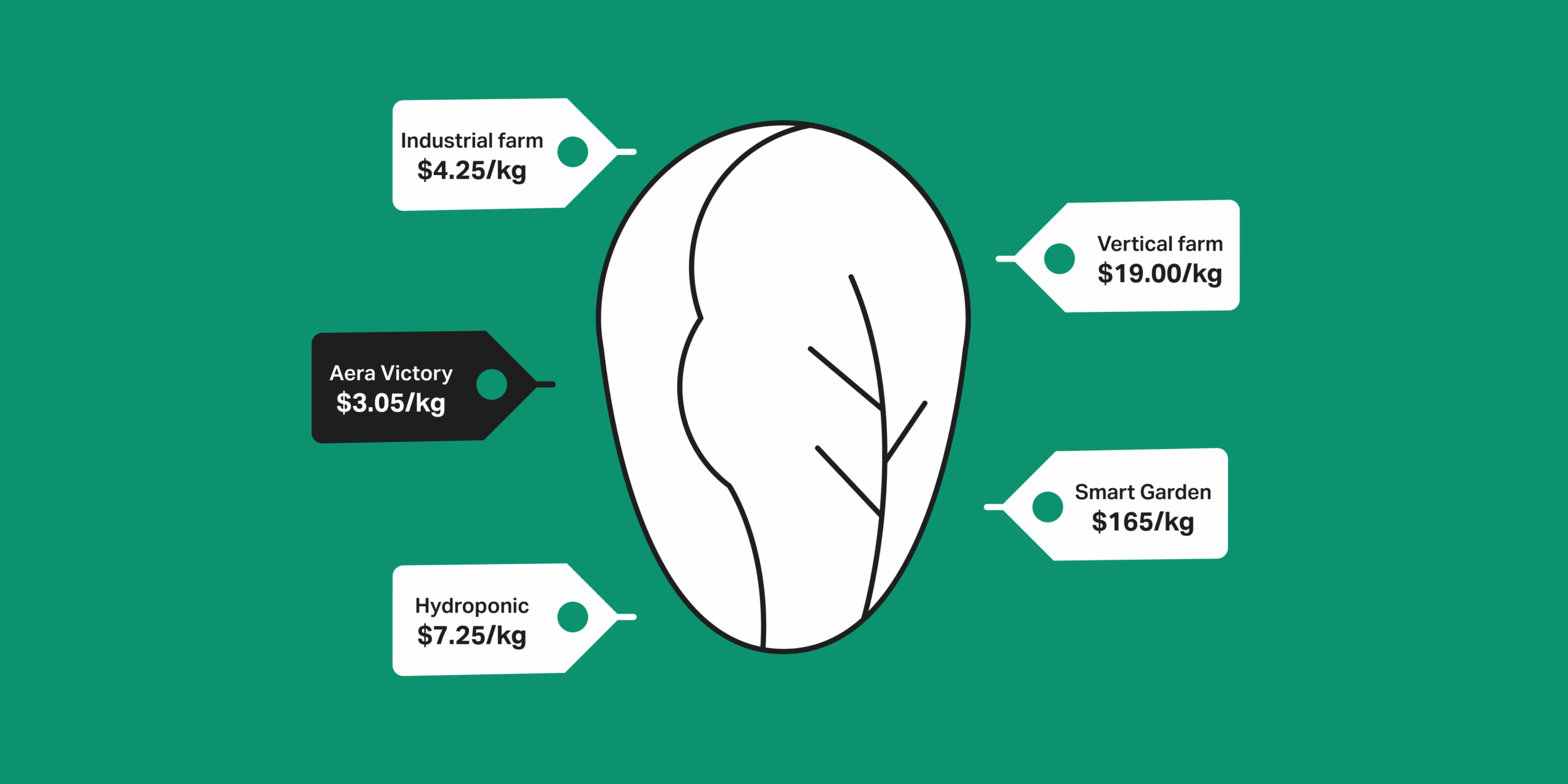

In recent years, innovations like hydroponic greenhouses and vertical farms have emerged as potential solutions to the challenges of traditional agriculture. However, they often come with trade-offs — including significant upfront capital expenditures, high ongoing operating and energy costs, and a reliance on skilled labor to manage complex systems.

These technologies are often owned by large companies or institutions, making them inaccessible to most households or communities. While they improve certain sustainability metrics, they still need further technological advancements to truly shift the dynamics of our food system.

Hydroponic Greenhouses

Hydroponic greenhouses grow plants in nutrient-rich water, often achieving higher yields than soil farming. For example, this study shows lettuce yields can reach up to 3.8 kg/ft² annually, compared to 0.36 kg/ft² in traditional field agriculture. However, they also consume up to 82× more energy per kg than conventional soil methods.

In addition, these operations require trained horticultural technicians to monitor pH, nutrient levels, and system maintenance. Combined with CapEx and infrastructure demands, the cost of produce typically lands between $5–9 per kg.

Vertical Farms

Vertical farms stack crops in high-tech indoor environments, producing as much as 7.4–11.1 kg/ft²/year. However, this productivity depends on intensive use of LED lighting, HVAC systems, and environmental automation — all requiring engineers, technicians, and operations managers to oversee daily performance.

Vertical farms also consume up to 38.8 kWh of electricity per kilogram of produce, making them one of the most energy-intensive farming systems available. Combined with high infrastructure and technology requirements, produce from vertical farms often retails at $13–25 per kg.

Indoor Smart Gardens

Smart gardens are marketed as consumer-friendly growing appliances, using automation and sleek design to make home growing accessible. However, they’re typically locked into proprietary seed pod systems — creating a razor-blade model that drives up the cost per harvest. Most systems yield only a few grams of herbs or lettuce per week, with cost per kg often exceeding $100 when accounting for proprietary pods, electricity, and yield per cycle.

While these systems don’t require external labor, they aren’t viable for meeting significant food needs and are often more about lifestyle or novelty than true sustainability or food sovereignty.

Gardening and Local Farmers

Traditional home gardens and local farms can be incredibly rewarding — they build food skills, strengthen communities, and offer a sense of connection to the land. But they’re also seasonal, weather-dependent, and limited by land, labor, and infrastructure. Most gardeners and small-scale farmers can only grow part of the year, and for a limited number of people.They’re an essential part of the solution — especially for community resilience and education — but not a substitute for scalable, year-round food production. To build a food system that works for everyone, we need technologies that extend access, increase efficiency, and complement these grassroots efforts, not replace them.

Why Victory Outperforms Every Growing System

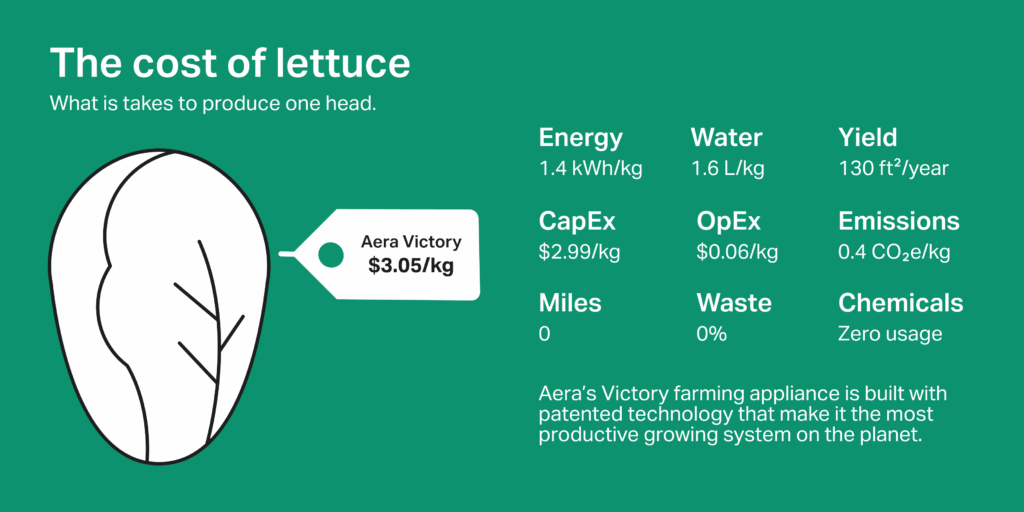

Aera’s Victory farming appliance is built with patented technology and smart design that make it the most productive growing system on the planet. Here’s why:

1. Climate-Controlled Environments

Because Victory operates as an appliance inside your home or building, it takes advantage of the existing indoor climate and human presence. Unlike greenhouses or vertical farms, Victory’s controlled environment agriculture (CEA) system doesn’t require separate heating, cooling, or even CO₂ injection systems. That means less energy use, fewer infrastructure demands, and no downtime from outdoor conditions (or pests) — enabling year-round, stable productivity in any season or location.

2. Patented Growing System

Victory’s fridge-sized unit uses a unique lighting system and pod layout that supports up to 216 crop spots on both horizontal and vertical growing planes — all within just six square feet of floor space. Its auto-germinating seed tech and continuous harvest model enable users to stagger plantings and pick food daily or weekly. This combination allows Victory to deliver more yield per cubic foot than any other growing system, period.

3. Aeroponic Design

Unlike hydroponics — where roots are submerged in water — Victory uses aeroponics, suspending roots in air and misting them with nutrient-rich vapor. This method uses up to 98% less water (although our tests show 99%), accelerates growth cycles (up to 3x faster than soil with 30% more produce), and supports an unusually wide range of crops — including leafy greens, herbs, fruiting plants, and even root vegetables.

But beyond yield and efficiency, what sets Victory apart is that it delivers this performance without the trade-offs. No pesticides. No cold storage. No nutrient loss. No wasted produce. No emissions-heavy transport. And no subsidies. It’s not just a more sustainable system — it’s a more complete one that puts people back in control of their own food supply.

A Case Study: What It Takes to Grow a Head of Romaine

All of this sounds good in theory — but what happens when you put these systems side by side? To show the full picture, we’ve compared Victory with every major category of food production: from soil-based farms to hydroponics, vertical farms, and consumer-grade smart gardens. What emerges is clear: Victory doesn’t just compete — it leads across every major metric, from water and energy use to yield per square foot and total cost per kilogram — even for the most cost efficient crops like lettuce.

Based on our early internal growing data, a single Victory farming appliance can grow up to 800 kg of romaine lettuce per year in just six square feet – while using a fraction of the water, energy, and space. The result is the lowest cost-per-kg model for leafy greens (and much more for herbs and fruiting produce) while providing year-round production across a wider variety of crops, all without subsidies, fuel inputs, or hidden costs.And it’s not just about dollars and cents — the environmental advantages are just as significant. Victory eliminates the need for long-distance transport, chemical inputs, and cold-chain storage. It produces zero food waste and requires no pesticides or fertilizers, all while using dramatically less energy and water. Compared to conventional and high-tech alternatives, Victory delivers the lowest environmental footprint per kilogram — redefining what sustainability looks like in food production.

(Read more about our methodology at the end of the post).

Why Victory Offers a New Economic Model — Not Just a New Device

Rather than trying to “disrupt” agriculture with another centralized megastructure, Victory introduces a decentralized model: a high-yield, low-footprint appliance that allows food to be grown exactly where it’s consumed.

It’s not just about convenience. It’s about:

- Reducing reliance on globalized supply chains

- Lowering food costs over time

- Eliminating food waste through real-time harvesting

- Drastically cutting water and energy consumption per kg

It’s a shift from centralized production to hyperlocal cultivation, from fragile logistics to resilient autonomy.

And this is just the beginning.

We envision a decentralized network of food-growing communities — restaurants, local farms, homes, schools, offices, and community centers — each equipped with its own Victory. Together, these micro-farms form a distributed food infrastructure that is more secure, sustainable, and economically rational.

The Bottom Line

At the end of the day, no single solution can fix the food system alone. To meet our climate goals and feed a growing population, we’ll need a combination of tools — from more efficient farms to smarter greenhouses, community gardens to autonomous appliances. The good news is, technology is accelerating. Costs are falling. And with systems like Victory, we’re getting closer to a world where fresh, local, sustainable food is not a luxury — it’s the baseline.

Victory isn’t just another kitchen gadget or vertical farm. It’s a new foundation for a food system designed around year-round access, resource efficiency, and local resilience. In a time of rising costs and shrinking certainty, growing your own food – affordably, consistently, and beautifully – might be the most radical thing you can do.

Grow your own food

Reserve your Victory now to secure your spot and get exclusive pre-order offers.

Methodology

The data in both the cost and environmental tables is based on a mix of publicly available research, industry case studies, consumer product data, and Aera’s internal modeling. Our goal was to create a fair, apples-to-apples comparison between the dominant systems used to grow leafy greens — from large-scale industrial farms to countertop smart gardens.

Economic Metrics

Cost per kilogram is calculated by combining:

- Amortized capital costs (CapEx) per square foot, divided by yield

- Annual operating costs (OpEx) including electricity, water, pods, and maintenance

- Yield estimates based on average kg of romaine lettuce produced per square foot per year

For Aera Victory, we used real performance data from our appliance: 800 kg/year in ~6 ft², with an expected lifespan of 7–10 years. Vertical farm and greenhouse data are sourced from industry averages (e.g. Agritecture, NuLeaf Farms), while smart garden costs reflect consumer systems like Click & Grow and AeroGarden.

Consumer price shows the approximate grocery store price or market retail price per kg of leafy greens for each system. It includes:

- Grocery store markups (often 1.5–2.5× production cost)

- Losses from spoilage, packaging, transport, and distribution

- Premiums for greenhouse-grown or vertically farmed produce

- Some reflection of no current path to affordability at scale for this type of produce

Environmental Metrics

Environmental impact includes four key factors:

- Emissions per kg of produce (kg CO₂e/kg), representing full lifecycle impact (including transport, waste, and packaging where applicable)

- Food waste percentages, based on spoilage and shelf-life losses across each system

- Food miles, or average distance from production to consumption

- Chemical input levels, ranging from high pesticide use to fully pesticide-free systems

Emissions estimates for traditional agriculture are adjusted upward to reflect long-distance shipping, food waste, and synthetic input use. Vertical farm emissions are driven by energy intensity, though we note some operators use renewable energy sources. Smart garden emissions now reflect not just electricity but also recurring pod packaging and shipping impacts.